CM focus on technology su IPCM Magazine n.59

Conveyor XD37/45 P&F by Sercolor

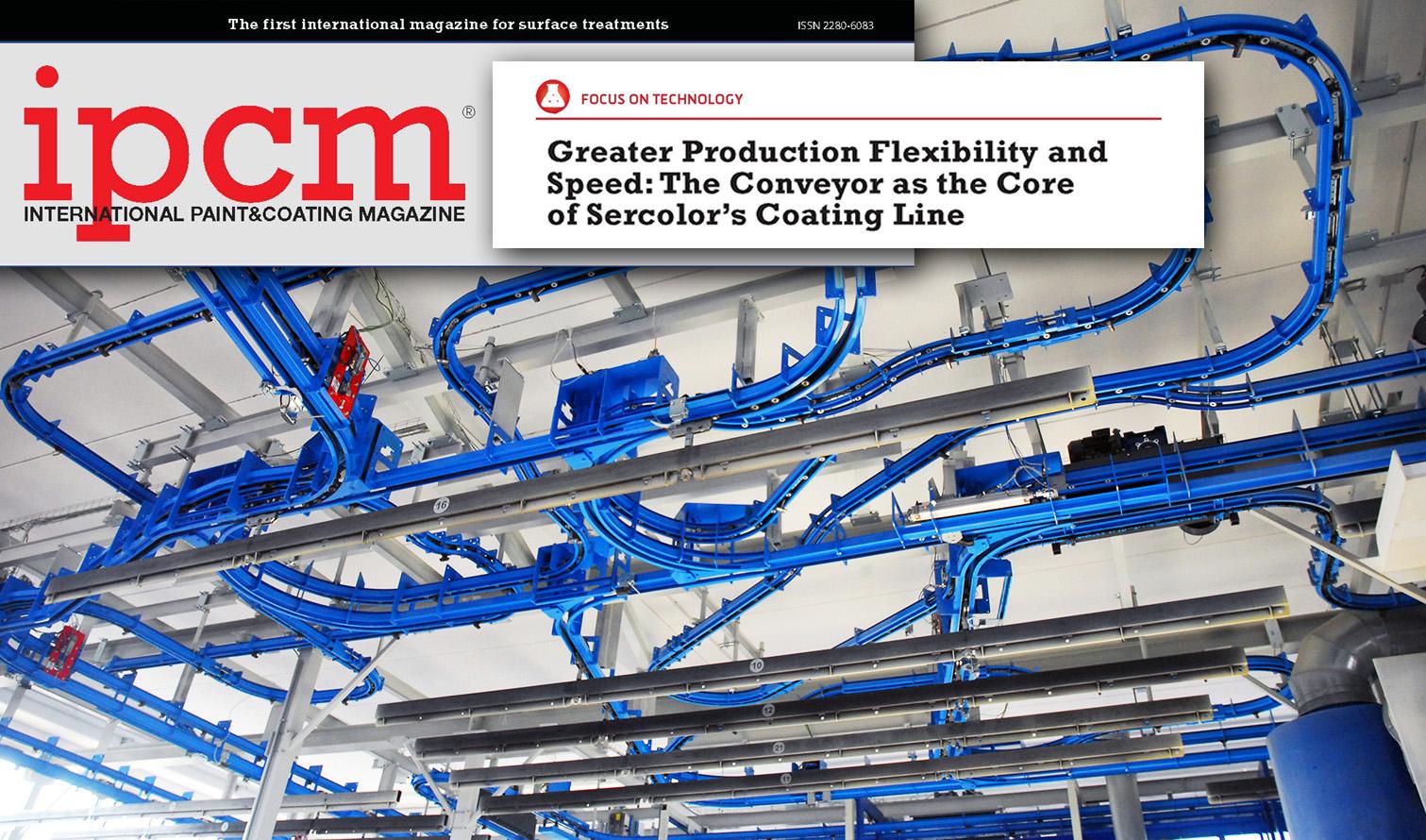

The complex structure of the new coating line

With a size of 6.5 x 5 x 2.5 m, the new coating plant is smaller than the other one (Fig. 2). “I have personally designed the layout of the new line based on the experience I have gained over the years,” states Serravezza. “Besides personally following the installation of each device, wherever possible I recovered parts of the old system that could be reused in the new line. The complexity of its structure reflects that of the painting cycle we perform in a limited space. This is the reason why one of the key players for the success of this project was the supplier of the handling system. Indeed, the conveyor is the core of a coating line (Fig. 3). Not only does it connect its different elements, but it also determines its pace and speed. An effective design that is functional to user needs is fundamental to manage both the plant’s operating and storage areas and to create an optimal production flow.

Our CM Automazione two-rail conveyor is now the core of our whole paintshop (Table 1, Figs. 4 and 5).